Closed, back open on monday from 8h to 12h and from 13h to 18h - +32 (0)9 355 74 26 - info@welda.be

Inspection of welding equipment

Get your welding equipment inspected, verified or repaired by Welda

Does your welding equipment need to be inspected, verified or repaired? Contact us, we will be happy to help you!

New standard NEN-EN-IEC 60974-14

It is important to periodically check welding equipment that is subject to wear. The guideline for this is at least once a year. Inspections are carried out according to the new international standard NEN-EN-IEC 60974-14 "Equipment for arc welding - Inspection in operation and testing". This standard replaces the old European standard NEN-EN 50504 "Validation of equipment for arc welding". The previous standard focused on “validation methods for arc welding equipment”, while the new standard specifies requirements for “verification of arc welding and external monitoring equipment”.

The most important points during the inspection are:

- Visual inspection

- Earthing of the safety circuit

- Insulation resistances of the primary circuit

- Open circuit voltage

This standard uses a checklist in which all important parts of the welding machine are checked. The welding machine can only be approved if it meets all the conditions. Moreover, problems such as pollution of the welding machine and defective or overloaded parts will no longer occur.

Checklist

During the visual inspection, the following must be checked:

1. Torch

Torch/electrode holder, welding clamp

- Check for water leaks

- Check for gas leaks

- Insulation testing of the welding torch using a megohmmeter

- Check the power cable

- Check control circuit

- General maintenance (replacing wear parts)

2. Welding machine

Main supply

- Faulty, damaged power cable

- Deformed, defective plug

Welding circuit

- Cables and couplings not suitable for intended use and performance

Case

- Missing or damaged parts

- Unauthorized modifications

- Blocked cooling vents or missing filters

- Signs of overload or misuse

- Missing or defective protective means, such as for example gas cylinder holder

- Missing or defective wheels, lifting equipment, holders,...

- Defective wire reel suspension

- Conductive objects placed in the case

Controls and indicators

- Faulty switches, gauges and lights

- Defective pressure regulator or flow meter

- Incorrect fuses accessible from outside the case

General condition

- Excessive dust or dirt

- Leak in coolant circuit or incorrect coolant level

- Defective gas hoses and connections

- Poor readability of markings and labels

Calibration, verification and validation

A welding machine should not only be electrically inspected, it is also important to calibrate, verify and validate it. Below we briefly explain the difference between these terms:

- Calibration: Demonstrate that the values displayed on the screen and the reference values match by testing.

- Verification: Demonstrate that the welding equipment meets the specifications set for the device.

- Validation: Demonstrating that the set values comply with the reference values within the specific limits.

Standard test or precision test

Welding devices with a display showing actual current and voltage values can be easily calibrated. If the welding device does not have a display, it must be tested in another way. This is then done on the basis of the set value. If there is a scale on the welding device, but it is not directly traceable to current or voltage, the device can be tested for consistency.

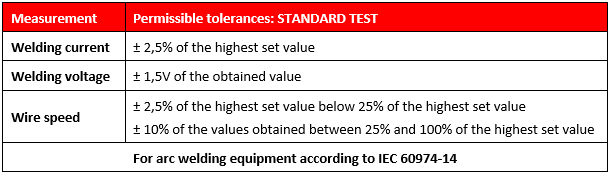

The determined values can be assessed with a standard test or a precision test. The standard test is the most commonly used. The deviations within which a welding machine can be approved can be seen in the table below.

End result

The result of the test must be stated on the welding machine with a sticker or label after the inspection:

- Passed

- Precision or standard test

- Date of test or expiration date

- Name of inspection organization

- Welding device serial number

In addition, an inspection certificate stating the test results must also be prepared.